Primary Force Standards (As Defined per ASTM E74)

Morehouse Deadweight Machine

ASTM E74 Standard Practice of Calibration of Force-Measuring Instruments for Verifying the Force Indication of Testing Machines (section 3.1.2) defines a primary force standard as a deadweight force applied directly without intervening mechanisms such as levers, hydraulic multipliers, or the like, whose mass has been determined by comparison with reference standards traceable to national standards of mass. To be classified as a primary standard the masses of the weights shall be determined within 0.005 % of their values. It is important to note that many state and commercial mass laboratories in the United States can adjust force weights too much better than 0.002 % of their values. Per section 6.1 of ASTM E74 weights are required to be made of rolled, forged, or cast metal. They shall have adjustment cavities that are capable of being closed by threaded plugs or suitable seals. The weights external surfaces shall have a finish of 125 or less as specified in ANSI B46.1.

Weights used as primary force standards require correction for local gravity and air buoyancy. It is very important the gravity value for the Laboratory’s location be established. Not establishing and correcting for gravity could result in significant errors, up to twenty times that required by the ASTM E74 standard. To avoid the need for mathematical corrections, it is strongly recommended weights be adjusted and calibrated for the gravity (g) at your Laboratory’s location.

Note: Your local gravity value can be calculated free of charge at the NGS website. Have your latitude, longitude, and elevation above sea level ready, and surf to http://www.ngs.noaa.gov/TOOLS/Gravity/gravcon.html, then push the button for gravity prediction. (If you need to find your latitude and longitude, www.whatsmygps.com can be useful)

Secondary Force Standards (As Defined per ASTM E74)

Morehouse Ultra-Precision Load Cells (0.005 % of full scale)

- Secondary Standards have a Class AA verified range of forces and must be calibrated by deadweight primary standards.

- The Class AA verified range of forces cannot be less than the lowest non-zero applied force.

- The Class AA verified range of forces cannot be less than 2000 times the resolution of the force measuring system.

- The Class AA verified range of forces is calculated by multiplying the LLF by 2000.

Working Standards

Morehouse Working Standard System

Working force standards are instruments used to verify testing machines in accordance with ASTM E4, Practices for Force Verification of Testing Machines. They may be calibrated by comparison with primary force standards or secondary force standards in accordance with ASTM E74. Working force standards range of use is limited by the Class A loading range. There are several important guidelines to remember when establishing the Class A loading range lower limit. These guidelines are as follows:

- Class A verified range of forces cannot be less than the lowest non-zero applied force.

- The Class A verified range of forces cannot be less than 400 times the resolution of the force measuring system.

- The Class A verified range of forces is calculated by multiplying the LLF by 400.

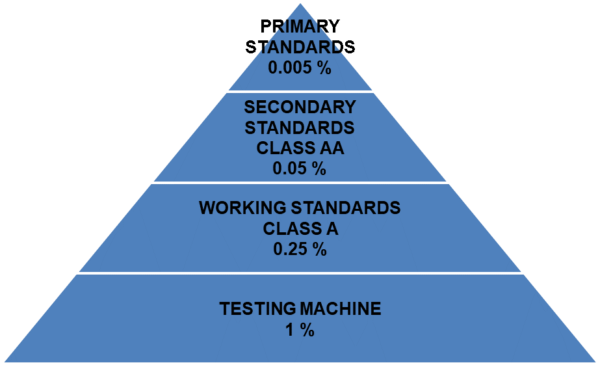

"In the world of calibration, Morehouse force laboratory calibrates three classifications of force standards, from least to most uncertainty: Primary(Morehouse Manufactures weights and subcontracts the calibration), Secondary (Morehouse uses our own internal Primary Standards for calibration), and Working (Morehouse uses Primary Standards and Secondary Standards that have been calibrated by NIST for these calibrations). The goal here is to maintain a traceability chain to a National Metrology Institute while adhering to accuracy compliance standards (specifically, ISO 17025 and ASTM E-74) for both internal and customer-supplied precision instrumentation. By fundamentally being a Primary force standard calibration lab, Morehouse is able to quantify devices with the least amount of error and uncertainty, while being flexible enough to certify any standard down the traceability chain. The figure below represents the ASTM E74 test accuracy ratios (TAR): TAR is a ratio of the accuracy of the Unit Under Test (UUT), and the reference standard used to calibrate the UUT

Primary force standard weights are determined within 0.005 % of their nominal values. 10:1 ratio when compared to secondary standards

Class AA verified range of forces for secondary force standards. 5:1 ratio when compared against working standards

Class A verified range of forces for working force standards. 4:1 ratio when compared to testing machines

A more detailed explanation of the ASTM E74 standard and procedure can be found here

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We challenge the "just calibrate it" mentality by educating our customers on what matters, and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.