What is Accuracy? Can We Trust the Manufacturer's Specifications?

What is Accuracy? Accuracy is influenced by both precision and bias in the measurement process. To understand accuracy, one must understand bias, systematic measurement error, random measurement error, measurement error, and precision.

Manufacturers' accuracy specifications may be misleading as they may not tell you how the measurement and test equipment actually performs during calibration and use. We have observed numerous instruments that do not meet the stated accuracy specifications

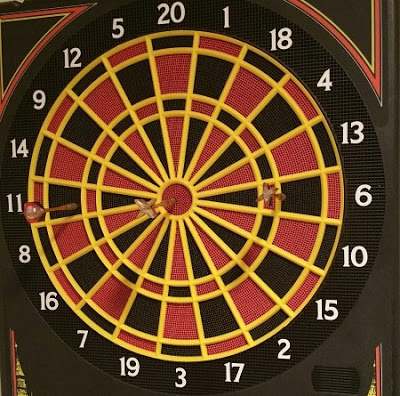

Accurate if we only look at the mean

If we only threw one dart and it hit the target, this may be a single-measurement bliss scenario. However, multiple darts reveal random measurement error to be large (each additional throw was about 160 mm off-target in opposite directions). Did the manufacturer use repeated measurements, or the first measurement when they wrote the specification? If they used the mean of -160 mm, 0 mm, and + 160 mm, the average would be zero.

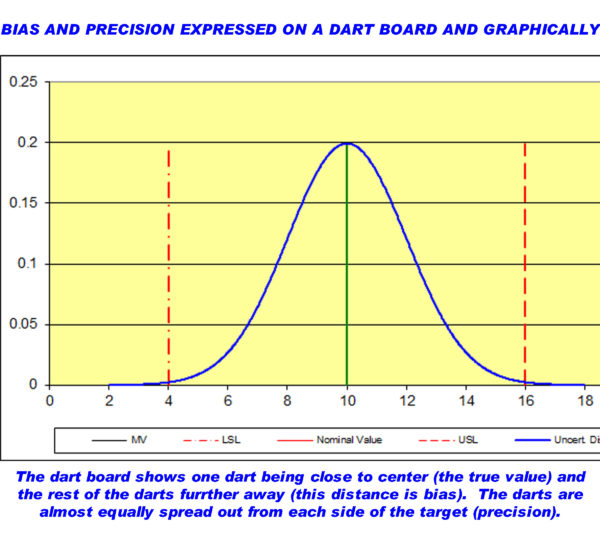

When we plot the precision of the person throwing darts graphically, we can see the average would lie on our target value. The standard deviation of these throws combined with the bias (mean of the repeated throws) will give us the true accuracy.

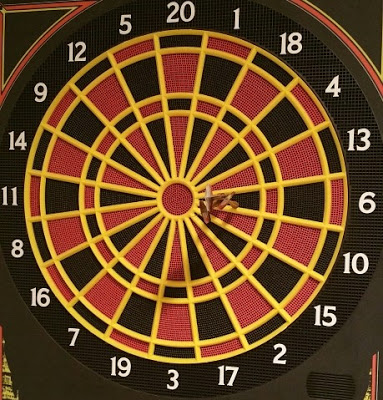

| Precise throw with some bias. |

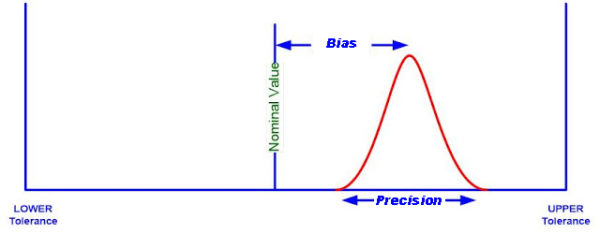

In the graph above the accuracy can be stated by the lower, and upper tolerances. All measurements made fall into the tolerance specifications. The manufacturer's accuracy specification would be credible. In this scenario, it may be very easy to make adjustments, which will lower the measurement error.

What is Accuracy?

- Accuracy is the function of bias and precision (estimate of systematic measurement error)

- The Qualitative term for the extent of the approximation of the measurement result to a "true value" (DIN55350)

- The closeness of agreement between a measured quantity value and the true quantity value of a measurand (VIM 2.13)

- Accuracy is a qualitative term as it is defined as a reference to a true value that is unknown

What is Bias?

- Measurement bias (bias): an estimate of systematic measurement error (VIM 2.18)

- Bias is a Qualitative term

- Bias is how close something is to the true value

- Bias is often characterized by finding the mean of repeated measurements

What is Systematic Measurement Error?

- Systematic Measurement Error: component of measurement error that in replicate measurements remains constant or varies in a predictable manner (VIM 2.17)

What is Measurement Error?

- Measurement Error: measured quantity value minus a reference quantity value (VIM 2.16)

What is Random Measurement Error?

- Random Measurement Error: a component of measurement error that in replicate measurements varies in an unpredictable manner (VIM 2.19)

- Note: Random Measurement Error equals Measurement Error minus Systemic Measurement Error

What is Precision?

- Precision is a measure of spread.

- Precision refers to the repeatability of the measurement

- Closeness of agreement between indications or measured quantity values obtained by replicate measurements on the same or similar objects. (VIM 2.15)

- Measurement precision is used to define measurement repeatability, intermediate measurement precision, and measurement reproducibility.

- Precision is often characterized by finding the standard deviation of multiple measurements

What is Accuracy? - Conclusion

Regardless of the manufacturer's specification sheet, it is important to have your equipment calibrated the way it is being used. The best practice is to put in place a measurement assurance system (practices put in place to monitor a testing or calibration process and to ensure the calibration status of equipment, reference standards, or reference materials used in the measurement process), and have your equipment calibrated at the proper intervals.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We challenge the "just calibrate it" mentality by educating our customers on what matters, and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.