How to Avoid Load Cell Cable Length Errors

The majority of force or torque systems we calibrate each year consist of load or torque cells, an indicator or readout, load cell cables, adapters, and some sort of shipping or carrying case. Around 90 % of these systems come in with an indicator only capable of supplying an excitation to the bridge and measuring a signal coming back from the transducer. This is known as a 4-wire system. A difference in load cell cable length in a 4-wire system will have large measurement errors.

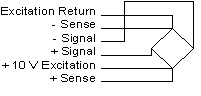

We are going to discuss the difference between true 6-wire systems. If you are using a 4-wire system, we hope to convince you the benefits of switching to a 6-wire system far outweigh the disadvantages of continuing to use a 4-wire system, and the 6-wire setup can eliminate almost all the errors associated with load cell cable length.

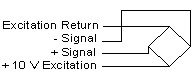

4-wire systems

| 4-wire cable |

| 4-wire Load Cell Cable Length Diagram |

In understanding the errors associated with a 4-wire cable, we must first understand why this error exists. In general, cable resistance is a function of temperature. The temperature change on a cable affects the thermal span characteristics of the load cell/cable system. On a 4-wire cable, this will affect thermal span performance. Simply put, as the temperature changes, the resistance of the cable changes and can cause a voltage drop over the cable length. A 4-wire setup simply cannot compensate for variations in lead resistance.

Substituting a cable of a different gauge or varying the load cell cable length will produce additional errors. A known example of this involves changing a 28-gauge or 22-gauge cable. The errors associated with load cell cable length on a 28-gauge cable will have a loss of sensitivity of approximately 0.37% per 10 feet of 28-gauge cable. On a 22-gauge cable, there will be a loss of sensitivity of around 0.09% per 10 feet of 22-gauge cable.

6-Wire Load Cell Cable Length Diagram

Pictured Above: Morehouse HADI 6 Wire System

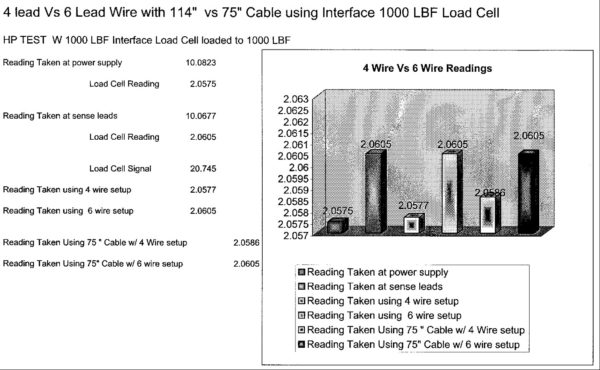

The testing we conducted at Morehouse

| Test Morehouse conducted back in early 2000 showing what happens when you vary the load cell cable length on 4 wire systems. |

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We challenge the "just calibrate it" mentality by educating our customers on what matters, and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.

#load cell cable length