What Makes a Force Calibration Machine Fit for Use? - Intro

Figure 1: Morehouse 1,000 lbf automated deadweight machine

At Morehouse Instrument Company, we’re justifiably very proud of our 1,000 lbf Automated Deadweight Machine. You can see in Figure 1 (above) that the force calibration machine looks level and square. What the picture doesn’t show is the rigidity of the machine, how plumb the weights are, or the adapter interface used.

Morehouse knows the key to achieving good calibrations is to make sure any force calibration machine is designed to be plumb, level, square, and designed to keep the line of force pure from eccentric loads. In addition, a deadweight force machine should incorporate some fundamental rules of physics. These include stacking the weights so larger weights are physically closer to the unit under test. This helps reduce the natural tendency or pendulum effect of weights when transferred to the unit under test.

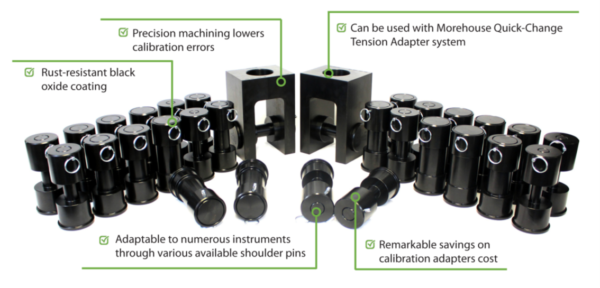

Of course, the best calibration practices do not stop at the machine level. Adapters play a crucial part in ensuring the calibration results are valid. Adapters should be designed to center the forces on the unit under test. In tension, this is usually accomplished by using tension adapters with two ball nuts and two ball cups. In compression, the preference is to use a ball seat and ball, spherical adapters, or adapters that direct the force to the unit under test. The typical recommendation for compression adapters is to have adapters that include one or two pads. Other aspects of adapters that are important include the size of the pin for tension links (shown in Figure 2, below), alignment plugs and base plates, and any other adapter designed to replicate how the force-measuring device is used in the field. Morehouse has a technical paper on adapters that can be found here.

Figure 2: Morehouse Clevis and Pin Sets

Now, back to what makes a great force calibration machine. In this blog, we are going to show what happens when a machine is out-of-level. Morehouse recently built a 10, 000 lbf deadweight force machine and, as an experiment, decided to level the machine by sight to see what would happen.

The machine was designed for minimal deflection under load (rigidity). It is square, and the weights on the yoke are designed to be plumb to each level. Since not every ground surface is even, most of our force machines are designed with legs that can be leveled. But isn’t it obvious when a machine is not level? After all, you can see when painting or picture you hang on a wall looks crooked, right? This is not the case when working with highly precise machines. It won’t be self-evident if the deadweight machine is 0.4 degrees off level, and that can happen very easily because most cement floors are considered level even if they vary by as much as a ¼ inch.

A side note here, when a manufacturer gives a spec for the flatness of microinches and the actual use is on a pavement, how in the world will the device behave when used on the pavement? Will it maintain tolerance? Morehouse has observed scale manufacturers using these specifications, and while it is great practice, we also need to consider how the machine is used in practice. So, the best machines and adapters may produce great results, but if the end-user is deviating from what was done during calibration, then the chances of maintaining the accuracy specification are going to decrease greatly. Therefore, it is always important to test devices for how they are going to be used. Alignment tests using bearing pads can be conducted to show how the unit reacts when on uneven surfaces or if the machine is misaligned.

The major point here is that a machine’s true level always needs to be verified. Let’s look at calibration results when a machine is leveled by sight versus using an actual level.

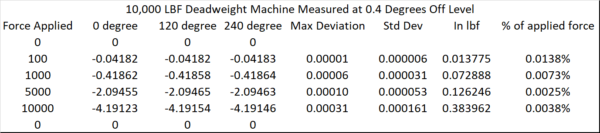

Figure 3 Data from a 10,000 lbf Morehouse load cell without checking the level

Figure 3 shows data from a 10,000 lbf load cell in a 10,000 lbf Morehouse deadweight machine when the machine was leveled visually. When measured with a level, the machine was found to be off-true by 0.4 degrees. The results of the calibration may be acceptable to some, but the data illustrates the side forces force are such that when the load cell is rotated, it has different deflection values. These deviate by as much as 0.00031 mV/V, or 31 counts out of 400,000 plus.

Many people might be content with results that show a deviation of only 0.0038 % or 0.384 lbf at capacity. However, this load cell should perform better. You should also remember that not all load cells react the same way; some are much more sensitive to rotational issues often associated with the machine not being level, plumb, square, or rigid enough where things start to bend. The Morehouse load cell has a very good side load sensitivity specification and tends to mask some machine shortcomings if one does not know the exact performance to expect.

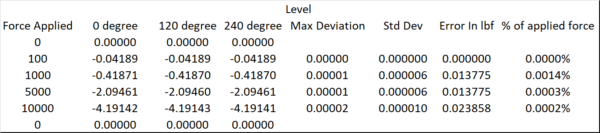

Figure 4 Data from a 10,000 lbf Morehouse load cell with machine-verified level

So, what happens when we level the machine to within 0.05 degrees? Figure 4 shows the same load cell tested in the same orientations of 0-degree, 120-degree, and 240-degree. The biggest difference is the deviation between runs is now 2 counts out of 400,000 plus, which is over 15 times better than the previous test. Additionally, the standard deviation at capacity is now 0.024 lbf (or roughly 0.0002 %). The repeatability of the load cell in rotation has gone from acceptable to fantastic. At capacity, this load cell repeats within 0.0002 % when rotated. If we were calibrating to ASTM E74 standards, this would translate to a Class A verified range of forces better than the first non-zero test point (in this case, 100 lbf). This means the load cell calibrated on a Morehouse deadweight machine is level in addition to being plumb, square, and rigid. This cell could be used for ASTM E4 calibration from 100 lbf through 10,000 lbf.

In the end, purchasing the right force machines and adapters will allow for the best calibrations of force-measuring equipment. Great force calibration starts with purchasing machines that are plumb, square, rigid, and allow the end-user to level them for the room in which they’ll be used. Without using a level, the readings will lead to substandard calibrations. The right adapters combined with machines that are plumb, level, rigid, and square will yield the best results.

Newer Morehouse UCMs from 2017 onward are more rigid than older models. These deadweight machines are designed with a superior distribution of the weights as well as more rigidity, so bending is minimized. Our new scale calibrators are designed so bending is minimized to less than ten-thousandths of an inch. Overall, every new Morehouse machine has been improved because we want our end users to have excellent calibration results.

What Makes a Force Calibration Machine Fit for Use? - Outro

Learn more about force-calibrating machines.

For our technical paper on calibration adapters, click this link.

For more information on our deadweight machines, please click here.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

I take great pride in our knowledgeable team at Morehouse, who will work with you to find the right solution. We have been in business for over a century and focus on being the most recognized name in the force business. That vision comes from educating our customers on what matters most and having the right discussions. Morehouse will not commit to providing a system if we cannot meet your expectations.

Everything we do, we believe in changing how people think about force and torque calibration. We challenge the "just calibrate it" mentality by educating our customers on what matters, and what causes significant errors, and focus on reducing them.

Morehouse makes simple-to-use calibration products. We build awesome force equipment that is plumb, level, square, rigid, as well as provide unparalleled calibration service with less than two week lead times.

Contact us at 717-843-0081 to speak to a live person or email info@mhforce.com for more information.