How to Calibrate S-Beam or S-Type Load Cells and Achieve Good Results

Figure 1 General S-Beam Load Cell

General Overview of S-beam or S-Type load cells

S-beam or S-Type load cells were designed for several weighing applications. Most were designed to be mounted on a scale, used as a lifting system, or process weighing for hopper and suspended tank weight measurement. They are typically not the right choice for several force applications requiring calibration to the following standards such as ASTM E74, ASTM E4, ISO 376, and ISO 7500. These load cells work by placing a weight or generating a force on the load cell's metal spring element. The weight on the load cell causes elastic deformation. The strain gauges in the load cell measure the fractional change in the length of the deformation. There are generally four strain gauges mounted in the load cell, and an indicator is used to measure the change in resistance of the strain gauges.

Figure 2 S-Beam Load Cell Loaded Flat on Bottom and with Morehouse Threaded Ball Adapter on Top

Why S-Type Load Cells are Not a Good Choice for Force Application

This article is going to show examples of challenges anyone using S-Beam load cells will face when trying to use this type of cell for force calibration. When the S-beam cells are mounted in place, they can be calibrated by weights, and the elastic deformation of the load cell will most likely allow the measurement to be repeated with acceptable results. However, when these load cells are used as transfer standards or people try to use them to measure force, they are typically not mounted in place and present several challenges. The challenges range from alignment as the load cells are susceptible to off-axis loading from various types of fixturing and adapters.

S-Type Load Cells Calibration Challenges

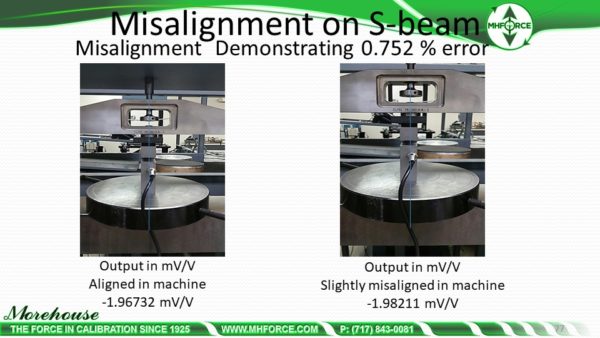

Figure 3 Slight Misalignment of S-Beam Load Cell Showing Large Errors (Slide Taken From Morehouse Training Class)

Misalignment

The S-Beam type load cells are susceptible to off-axis loading conditions, as shown in Figure 3. The S-beam was placed in our Morehouse deadweight machine, which is accurate to better than 0.002 % of applied force, and readings were taken with the load cell aligned. Then we just slightly misaligned, probably around 3 mm, and took another set of readings. The difference between the two measurements was approximately 0.752 %. This sensitivity to the slightest misalignment makes these cells very difficult to calibrate without using the proper adapters. The main issue is the calibration laboratory may have the appropriate alignment fixtures, but if this type of load cell was used in the field for ASTM E4 or ISO 7500, the technician would most likely struggle to achieve alignment. If the load cell was used to verify a force in a press or another force application, could proper alignment be achieved? We did the same test with a Morehouse shear web load cell and demonstrated an error of less than 0.0025 % in Figure 4, which is negligible. Both of these tests are shown via video and can be seen by following the links below.

Figure 4 Morehouse Shear Web Load Cell

Because the S-beam is so susceptible to off-axis loading, they are a better choice for applications where they can be permanently fixed into place. The best example would be mounted on a crane scale or other types of scales.

S-beam misaligned video link https://www.youtube.com/watch?v=15630Ab8YkU

Morehouse Shear Web misaligned video link https://www.youtube.com/watch?v=MgTWK2hRHLs&t=2s

Different Loading Conditions

Not only are S-beam load cells sensitive to the slightest bit of side load, but they also have relatively large errors if loaded differently from how they were calibrated.

Figure 5 Different Loading Adapters and Output from Changes in Loading Conditions

Figure 5 above shows different loading conditions and output of the S-beam load cell using different adapters and varying loading conditions. These conditions are loading through both top and bottom threads, which is preferred if symmetry error is a concern. Symmetry error is the difference in output between the maximum force in compression and the maximum force in tension. The symmetry of the S-type load cell, when loaded through the threads in both modes, is often very good. The next loading condition is loading tight against the top and bottom thread. This may be the least common loading application we see in the Morehouse Force laboratory.

The most common request we receive is for the S-type load cell to be loaded flat against the base in compression with using some sort of spherical top or ball adapter. We use an alignment plug to center on the base and use a threaded adapter with a ball to achieve the best alignment possible. This helps both the repeatability and reproducibility conditions of the load cell in our frame. Knowing that the S-beam load cells are so sensitive to any off-center loading, we highly recommend using machines that are built to be rigid, level, plumb, and square like the Morehouse machines we build and use in our calibration laboratory. The final picture far right shows flat-on-flat loading. This is not recommended as the output of the load cell will vary significantly as to where the force is actually transferred through the material. The amount of area of that interfaces with the top and bottom of the load cells will change the deflection.

In Figure 5, the worst error occurs when comparing the pictures on the far left and far right. The error is between loading the load cell through the threads and loading it flat on flat. This error had a maximum difference of 0.369%. In general, even the smallest error between the loading conditions loading through the threads versus loading flat on the bottom and through the threads on top had an error of almost 0.03%. Thus, it is imperative that the calibration laboratory and the end user communicate how the S-type load cell is being used. This should be done as part of the contract review. However, most companies fail to ask these questions, and most do not have this as part of the contract review. They get more concerned with accreditation and decision rules than what severely impacts the results, but that is another topic for another day.

S-beam load cells have issues. We are hopeful this article has shed some light on these issues and that you can make the necessary changes to improve your force measurements. These changes can be using a calibration provider such as Morehouse or changing out the S-beam load cell for something better like a Morehouse shear web load cell. It could be as simple as purchasing better adapters for alignment or making sure your load cells are being calibrated in a way that represents how the load cell is being used.

Calibrating s-beam load cells properly is essential to making measurements that matter. If you want to calibrate S-type or S-beam load cells with minimal errors, please feel free to contact us at 717-843-0081 or info@mhforce.com.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We challenge the "just calibrate it" mentality by educating our customers on what matters, and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.